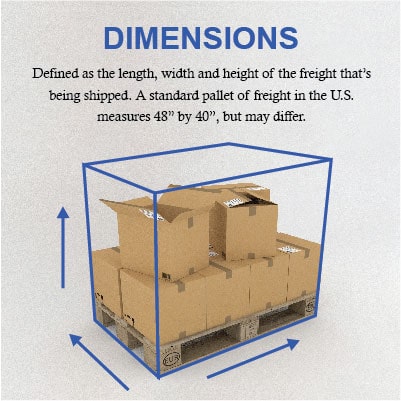

Carriers often require accurate dimensions in less-than-truckload (LTL) shipping. But why do they need dimensions? And how do you ensure you have the correct ones?

Let’s start at the beginning with the usual dimensions required.

Jump to:

Dimensions are calculated by the length, width and height of the largest part of what you’re measuring. With freight, you’ll often hear the pallet size fill in the length and width. You’ll then have to measure for the height to get your final dimensions.

Carriers then use all four measurements to assign your load to a trailer. A standard 53” trailer can only hold so much freight and weight, so ensuring your dimensions are as accurate as possible will help with:

- Minimizing possible damage to your freight

- Avoiding accessorials such as overlength fees

- Certifying the appropriate dock equipment is available to move your load

And when you throw standard-size pallets in with non-standard or tall freight, carriers will squeeze as much space out of a trailer as they can.

Now that we have the basics, let’s look at how dimensions can impact pricing.

Dimensions in Classifications & Pricing

Freight class is one detail that can greatly impact your freight pricing, especially for LTL shipments. It’s calculated based on your shipment’s length, width, height, weight and the “transportability” of your commodity. Learn more about freight class here.

The easiest way to determine your class is to use a density calculator. This tool will take your dimensions and weight to give you a rough estimation of your class. Most calculators are based on the National Motor Freight Classification (NMFC).

In the LTL world, carriers often optimize the space in their trailers by looking at the dimensions, weight and class and fitting pallets together to reduce wasted space. Below is a great example of optimizing trailer space with width and length only. This doesn’t take into account stacked pallets.

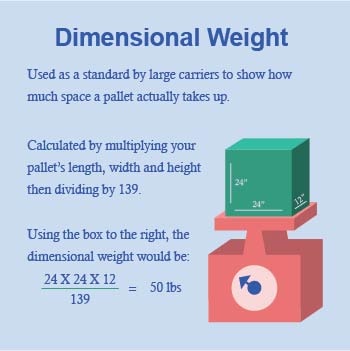

Carriers may also calculate your dimensional weight to give quote estimates.

Dimensions not only impact your freight class, but also your pricing.

For example, in air freight, there are maximum cargo dimensions for standard shipments. This is due to the maximum space a plane’s cargo area can hold, and since one shipment will most likely not take up the entire plane, taking up more space will often cost more.

The same goes for LTL shipping. Pallet rates often increase with freight class, and if you ship lighter, less dense pallets that are tall or unstackable, carriers may charge you more because of the space your shipment takes up.

But how can carriers tell exactly how much space is taken up if they use estimated dimensions and weight?

This is where freight dimensioners come in.

Rise of Dimensioners & Accessorials

Many large freight carriers have added dimensioners to their facilities to help with having the most accurate pallet dimensions and weight as possible.

Pallet dimensioners are machines that measure the length, width and height of an entire pallet of freight. They’re often used together with weighing scales and cameras that capture a photo of the freight.

Carriers use these tools to ensure that the dimensions given are accurate and do not exceed what the shipper told them they would be.

If dimensions exceed what was expected, this throws off the carriers’ process for optimizing trailer space. This may lead a shipment to be re-assigned to another trailer manually or delayed because a trailer is not available.

Carriers may also add a reclassification or reweigh accessorial fee to a shipment with different dimensions. The fee often covers the manual steps to correct the shipment.

For more on how to avoid these fees, check out our post 3 Tips to Avoid Freight Reclassification & Reweighs.